產品

シャーワヘッド | バイオフイルター | 薄膜リアクターバイオフイルター

With our unique expertise and experience in Microbiology, our Research and Development Department has applied the latest technical know-how to provide a total solution for the off-gas emission control.

The BIO-FILTER is applying both biological and physical methodologies to tackle the problem of off-gas. It contains a selected range of microorganisms grown in a sealed container. Utilizing the natural metabolic activity of microorganisms, it converts contaminants into CO2, H2O, NO3 and (SO4)2-. The packing material is a composite of natural fibrous substance, and is clean and safe.

PRINCIPLE OF THE BIO-FILTER

Waste gases contain pollutants that can cause odor or other adverse effects on the environment (corrosion, health hazard, crop damage, smog formation, and etc). Bio-filters can remove pollutants from waste gases under the condition that these pollutants are biodegradable and readily soluble in water. In bio-filtration, the gas to be treated is forced through a packed bed with material to which microorganisms are attached as a bio-film.

Biodegradable volatile compounds are absorbed by the bed material and the bio-film and subsequently biologically oxidized into less harmful substances like CO2, H2O, nitrates and sulfates. The microorganisms use the pollutants as substrate for growth and /or energy supply. Besides the pollutants, the microorganisms need other nutrients with elements like N, P, S, K, Ca, Mg, Fe, trace elements, and depending on the type,CO2.

Since the bio-film is an active part, it will work constantly under a controlled temperature condition to dissolve the odor compounds in the waste gas. The selected microorganisms are tested and proven safe to human kind. With regular maintenance, the expected life circle of the microorganisms can be from 4 to 10 years.

The bio-film which grows on the packing material take up the pollutants and degrade them:

H2S + 2 O2 → H2SO4

NH3 + 2 O2 → H2O (nitrification)

Organic compounds + O2 → CO2 + H20

SAFETY

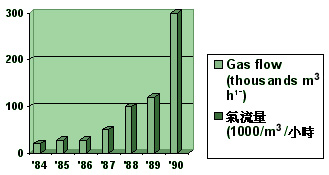

From the late 70s, most of the research and development on biological off-gas treatment has been carried out in Germany and The Netherlands. The bio-filter is certified as the most safe and economic device for the treatment of off-gas. In Holland the increment of using bio-filter to tackle the off-gas problem has been increased tremendously in the past 10 years.

In the Netherlands more than 400 bio-filters are running at sewage plants. They are now regarded as the best method to treat gases from sewage treatment plants. They are environmental friendly and cost effective. The gases from the sewage treatment plant mostly contain odorous compounds, like H2S, volatile fatty acids, organ sulfur compounds (methanethiol, dimethylsulfide, dimethyldisulfide) and amines. The optimal removal rate of the bio-filter is 98% of H2S and odor and its life expectation is up to 20 years.

The waste gases from garbage collection station and toilet are mainly from organic compounds. By using different microorganisms and packing material in different type of containers. We have designed our products to fit both indoor and outdoor environment.

|

Application

|